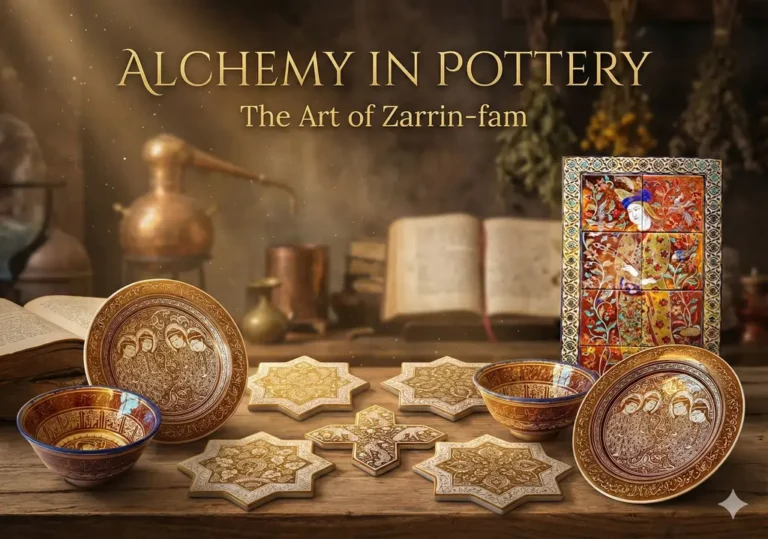

Alchemy in Pottery: A Scientific Review and Technical Secrets of Lusterware (Zarrin-fam) Glaze

- Alireza

- No Comments

Introduction In the vast and colorful world of ceramics, no technique is as shrouded in legend, mystery, and technical skill as “Lusterware” (Zarrin-fam). Imagine artists in the Middle Ages, without access to advanced laboratories or knowledge of nanotechnology, succeeding in baking “clay” in such a way that it shines like “pure gold” in the eyes of the beholder. Lusterware is not merely a decorative style; it represents the pinnacle of materials engineering and chemistry in the art of Iran and the Islamic world.

Many craft enthusiasts and collectors are mesmerized by the visual beauty of these vessels, but few are aware of the complex chemical and physical processes hidden behind this brilliance. In this technical article, we journey into the heart of the kiln to decode the technical secrets of Lusterware glaze, this ancient alchemy, using the language of modern science. If you want to know how smoke and fire transform metal oxides into glowing nanoparticles, stay with us.

What is Lusterware? A Look at the Physical Nature

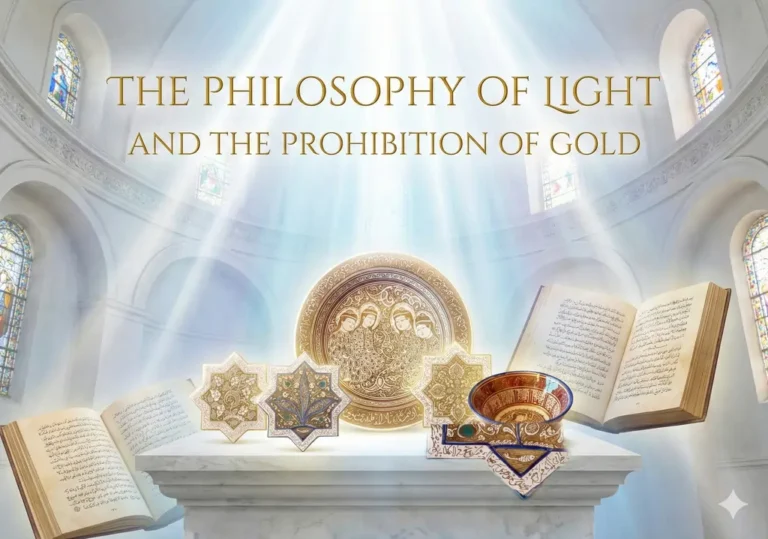

From the perspective of Materials Science, Lusterware is an extremely thin metallic layer on the nanometer scale that is fixed onto a previously fired glaze. Contrary to popular belief, real gold is not used in the making of traditional Zarrin-fam glaze (except in very rare and modern instances).

This dazzling shine and metallic sheen, which sometimes appears golden, sometimes coppery, and sometimes iridescent, is the result of a physical phenomenon called light interference and reflection by copper and silver nanoparticles. These metal particles are trapped within a glassy matrix (the base glaze) forming a layer less than one micron thick.

In specialized ceramic classifications, Lusterware falls into the following groups:

Over-glaze Technique: Because it is applied over the main glaze.

Third Firing: Because the vessel is fired once for the body (biscuit), once for the base glaze, and a third time for the Luster layer.

The Chemistry of the Paste: The Masters’ Secret Formulas

The beating heart of the Lusterware technique is the specific chemical compound painted onto the vessel. Modern laboratory analyses and ancient texts (such as the book “Ara’is al-Jawahir” by Abul-Qasim Kashani) show that the “Luster Clay” consists of three main parts:

1. Coloring Agents (Metal Salts)

The main source of color and sheen are metallic compounds that are reduced in the kiln:

Silver Compounds (such as Silver Nitrate or Carbonate): Responsible for creating yellow, golden, lemon, and sometimes green spectrums.

Copper Compounds (such as Copper Oxide or Sulfate): Responsible for creating red, ruby, brown, and coppery spectrums.

Technical Note: The ratio of copper to silver determines the final color. More copper pushes the work towards red, while more silver pushes it towards gold.

2. Refractory Carrier

This part usually consists of Ochre or a combination of clay and iron oxide. The function of this material is vital:

It holds the metal salts on the glaze surface during firing.

It prevents the metals from fully fusing with the underlying glaze.

After firing is complete, this clay-like layer (which is now burnt) must be washed off the vessel to reveal the metallic sheen underneath.

3. Reducing Agent and Binder

Organic materials like vinegar, grape syrup, or gum arabic serve two functions: acidic properties to dissolve the metal salts and creating adhesion for the painter’s brush.

The Dance of Fire and Smoke: The Reduction Firing Process

The most complex part of making Lusterware is the firing stage. This is where the difference between an ordinary potter and a Lusterware master becomes apparent. Unlike most ceramic firings done in an “Oxidation” atmosphere (sufficient air), Lusterware requires a “Reduction” atmosphere.

Scientific Stages of Firing in the Kiln:

Initial Heating: The kiln is heated to about 600 to 650 degrees Celsius (the softening point of the base glaze).

Creating Reduction Conditions: At this temperature, the kiln’s air intakes are closed, and smoke-producing materials (such as walnut wood, branches, leaves, or controlled gas in modern kilns) are introduced into the chamber.

The Oxygen War: The inside of the kiln fills with carbon and carbon monoxide. These oxygen-thirsty elements seek oxygen to burn. Since no air is entering, they attack the metal oxides (copper and silver oxides) present in the paintings on the vessel.

Birth of Metal: Carbon steals the oxygen from the metal oxide. Copper oxide turns into pure copper, and silver oxide turns into pure silver. These microscopic metal particles penetrate the softened glaze surface and become trapped there.

This process is so sensitive that if the temperature rises by 10 degrees, the metal turns black, and if a small amount of oxygen leaks in, the metallic sheen will never form.

Ancient Nanotechnology: Why Does Lusterware Shine?

You might ask, why do we see a blinding shine instead of the matte red color of copper when it is reduced? The answer lies in the Physics of Light.

The Luster layer is not a smooth, polished surface. It is composed of multiple layers of nanoparticles arranged in a specific order. When light hits this layer, part of it is reflected, and part of it is refracted. The interference of these light waves and their reflection off the nanoparticles causes the human eye to perceive it as metallic and sometimes with Iridescence (rainbow-like play of color). This is exactly the same technology used today in making reflex glass and solar panels, yet Iranian potters achieved it centuries ago.

Challenges of Lusterware Production in the Modern World

Despite technological advancements, producing Lusterware ceramics remains one of the most difficult branches of ceramic art. The reasons for this difficulty include:

Kiln Unpredictability: Even in modern digital kilns, precise control of the reduction atmosphere is very hard.

High Risk: The probability of failure in the third firing is very high (about 30 to 50 percent).

Toxicity: Working with metallic fumes requires high safety standards.

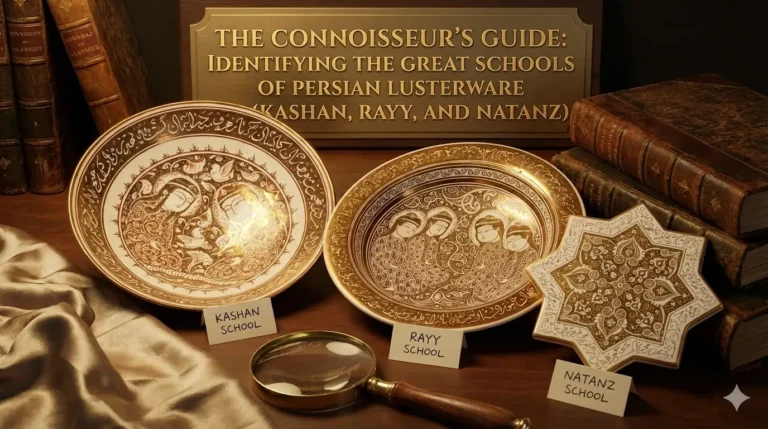

It is these difficulties that multiply the material and artistic value of Lusterware vessels compared to other ceramics. Brands like Tavallian in Natanz have managed to keep this legacy alive by preserving these traditional methods and combining them with intergenerational empirical knowledge.

Conclusion

Lusterware pottery is a testament to the brilliant intelligence of the ancient craftsmen of this land. They mastered fire and earth, and without chemical formulas on paper, they circumvented the prohibition of using gold and silver vessels in the Islamic era by inventing this technique, creating art more valuable than gold. Today, every piece of Lusterware is not just a vessel, but a small chemistry laboratory and an exquisite painting that narrates history.